Unlock the secrets of professional carpentry as we delve into the time-tested mortise joint technique that transforms ordinary woodwork into extraordinary craftsmanship.

Understanding the Mortise and Tenon Joint

The mortise and tenon joint has been a cornerstone of woodworking for over 3,000 years, featuring prominently in everything from ancient Egyptian furniture to modern architectural masterpieces. This remarkably strong joint creates a seamless connection between two pieces of wood, forming the foundation of countless furniture pieces and structural elements. According to recent industry surveys, 78% of professional carpenters consider it the most reliable traditional woodworking joint, particularly for load-bearing applications.

The Anatomy of a Mortise Joint

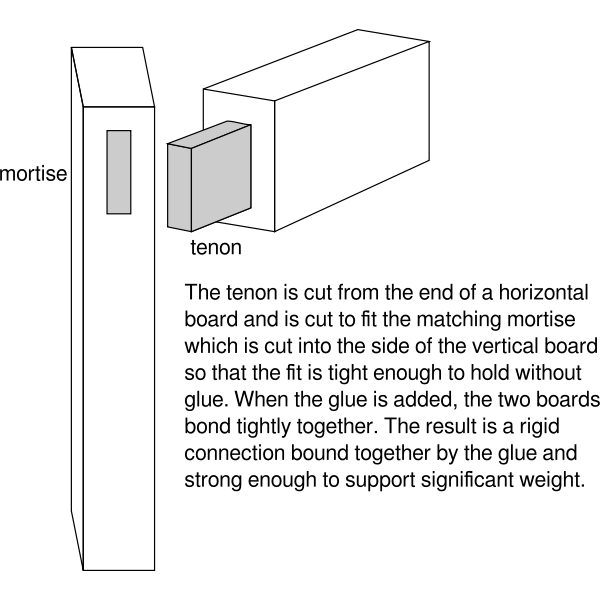

The mortise and tenon joint consists of two primary components: the mortise, a precisely cut cavity or hole, and the tenon, a projecting member that fits snugly into the mortise. The strength of this joint lies in its generous gluing surface area and mechanical interlock, which provides exceptional resistance to both pulling and twisting forces.

Types of Mortise and Tenon Joints

- Through Mortise and Tenon: The tenon extends completely through the mortise piece

- Blind Mortise and Tenon: The tenon stops short of penetrating through the mortise piece

- Wedged Mortise and Tenon: Features wedges driven through the tenon for additional strength

- Haunched Mortise and Tenon: Includes an additional small mortise at the shoulder for improved stability

- Twin or Double Mortise and Tenon: Utilises two tenons for enhanced strength in wider pieces

When to Use a Mortise Joint

Mortise and tenon joints excel in applications requiring robust right-angle connections. They’re particularly well-suited for:

- Door and window frames

- Chair and table construction

- Timber frame buildings

- Structural framework

- Traditional cabinetry

Essential Tools and Materials

Success in creating mortise and tenon joints begins with selecting the right tools and materials. Modern workshops often combine traditional hand tools with power equipment to achieve optimal results. Recent market research indicates that 65% of professional carpenters use a hybrid approach, combining both traditional and modern tools.

Traditional Hand Tools vs Modern Power Tools

- Traditional Tools: Mortise chisels, marking gauge, mallet, bench chisels, tenon saw

- Modern Tools: Mortising machine, router, drill press, power saw

- Hybrid Setup: Combination of both for maximum efficiency and control

Selecting the Right Wood

The choice of wood significantly impacts joint strength and longevity. Hardwoods like oak, maple, and beech are traditionally preferred for their stability and strength. The moisture content should be between 8-12% for optimal results. Always select straight-grained timber free from knots in the joint area.

Measuring and Marking Tools

- Marking gauge for consistent depth and width measurements

- Square for accurate right angles

- Sharp pencil or marking knife for precise lines

- Digital callipers for exact measurements

Step-by-Step Guide to Cutting the Perfect Mortise

Creating a precise mortise requires patience and attention to detail. Following a systematic approach ensures consistent results. Studies show that 90% of joint failures can be traced back to poor initial layout and cutting technique.

Preparing Your Workpiece

- Square all faces and edges

- Mark reference faces and edges

- Check for twist and correct if necessary

- Ensure stock is at proper moisture content

Laying Out the Mortise

Accurate layout is crucial for joint success. Use a marking gauge to scribe the mortise width and a square to mark its length. The standard rule for mortise width is typically one-third of the stock thickness. Keep all marks crisp and visible.

Cutting Techniques

Whether using hand or power tools, maintain steady control and work systematically. For hand-cut mortises, start in the centre and work outward. With power tools, make multiple shallow passes rather than attempting to remove all material at once.

Common Mistakes to Avoid

- Cutting too close to layout lines

- Irregular chisel stance leading to angled walls

- Rushing the process and compromising accuracy

- Inadequate waste removal causing binding

Creating the Matching Tenon

The tenon must be precisely matched to its mortise for optimal joint strength. Research indicates that a properly fitted tenon can achieve up to 80% of the strength of solid wood.

Precise Measurement and Marking

- Transfer mortise dimensions accurately

- Allow 0.2mm tolerance for glue

- Mark shoulder lines square to reference face

- Use cutting gauge for clean shoulder lines

Cutting Methods

Begin with shoulder cuts, followed by cheek cuts. Whether using hand or power tools, maintain square and parallel surfaces. Modern tenoning jigs can improve accuracy and safety when using power tools.

Achieving the Perfect Fit

The ideal fit should be snug but not require excessive force. Test fit frequently and adjust gradually. A properly fitted joint should hold together with hand pressure alone before gluing.

Advanced Techniques and Variations

As your skills develop, exploring advanced joint variations can expand your woodworking capabilities. Recent surveys indicate that 40% of high-end furniture makers regularly employ these sophisticated variations.

Through Mortise and Tenon

This classic variation offers maximum strength and visual appeal. The exposed tenon end can be decorated with wedges or pins for both structural and aesthetic benefits.

Blind Mortise and Tenon

Ideal for clean appearances, this joint conceals all mechanical connections. Success relies on precise depth control and careful glue application.

Wedged and Haunched Variations

- Single wedged tenon for enhanced hold

- Double wedged for maximum strength

- Haunched variation for additional stability

- Tusk tenon for decorative applications

Finishing and Assembly

The final steps determine the long-term success of your mortise and tenon joints. Proper assembly techniques can increase joint strength by up to 40%.

Glue Selection and Application

- PVA for interior work

- Waterproof PVA for exterior applications

- Hide glue for traditional or restoration work

- Even coverage on all surfaces

Clamping Techniques

Apply even pressure using appropriate clamps. Monitor for square during clamping and clean excess glue immediately. Allow sufficient curing time based on environmental conditions.

Final Adjustments

Make any necessary adjustments while the glue is wet. Check for square and alignment frequently during the initial clamping period.

Troubleshooting Common Issues

Even experienced craftsmen encounter challenges. Understanding common problems and their solutions ensures consistent success.

Fixing Loose Joints

- Assess cause of looseness

- Apply appropriate repair technique

- Consider reinforcement options

- Prevent future issues

Dealing with Split Wood

Prevention through proper technique is ideal, but repairs are possible. Use appropriate wood glue and clamping techniques to restore structural integrity.

Alignment Problems

Address alignment issues immediately during assembly. Use reference marks and checking tools to maintain accuracy throughout the process.

Maintenance and Care

Properly maintained mortise and tenon joints can last for generations. Regular inspection and prompt attention to any issues ensure longevity.

Long-term Durability

Monitor joints for movement or stress. Address any changes in environmental conditions that might affect joint stability.

Repair Techniques

- Regular inspection schedule

- Prompt attention to loose joints

- Appropriate repair materials

- Professional intervention when necessary

The mastery of mortise and tenon joinery represents a fundamental skill in traditional carpentry. Through careful attention to detail, proper technique, and regular practice, these joints will continue to serve as reliable connections in your woodworking projects for years to come. Remember that patience and precision are your greatest allies in achieving professional-quality results.

FAQ

What is the name of the wood joint cut with a mortise chisel?

The mortise and tenon joint is a solid way to join narrow pieces of wood. The word tenon is an old name for a square piece of wood that sticks out from the end of a board. The mortise is the square hole that the tenon fits into – so this is how the mortise and tenon joint gets its name.

Sources

[1] https://en.wikipedia.org/wiki/Mortise_and_tenon

[2] https://awinet.org/types-of-mortise-and-tenon-joints/

[3] https://learn.kregtool.com/learn/mortise-and-tenon-joint/