Is the G10 Pencil the Secret Weapon of Professional Carpenters?

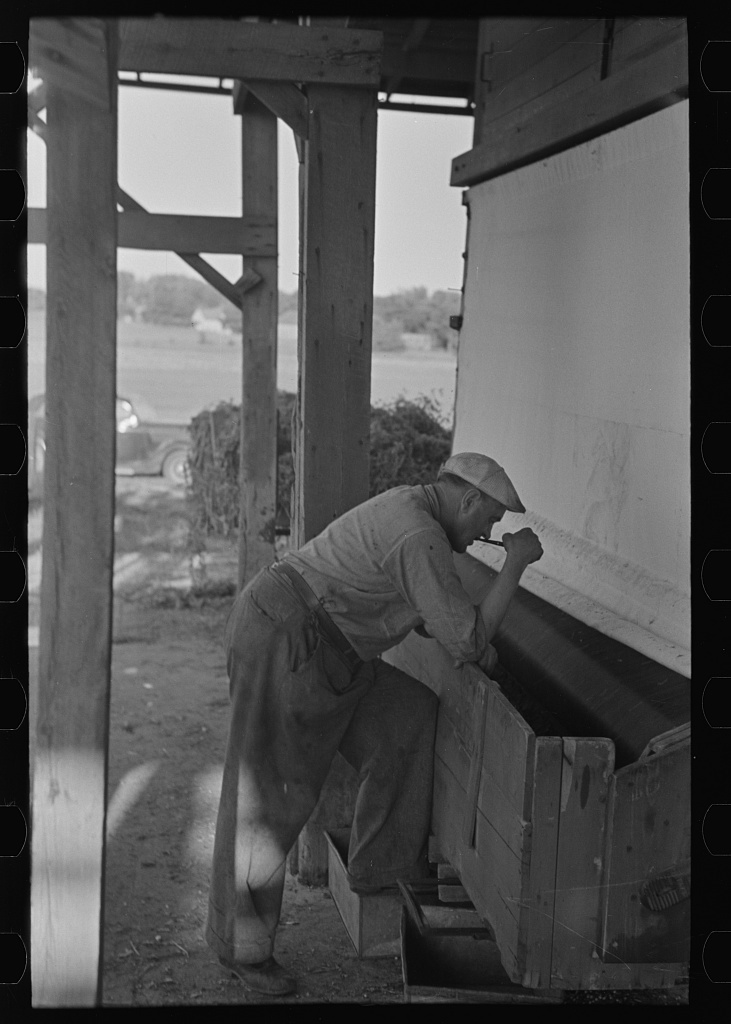

Discover why master craftsmen swear by the precision of the G10 pencil for flawless carpentry layouts and markings. For generations, carpenters have relied on their tools to achieve precision and perfection in their craft. Among these tools, the marking implement they choose can make all the difference between mediocrity and mastery. In recent years, a revolutionary tool has emerged that’s changing how professional carpenters approach their work – the G10 pencil. Understanding the G10 Pencil Revolution The G10 pencil represents a significant leap forward in marking technology for professional woodworkers. Unlike traditional carpenter pencils, which have remained largely unchanged for centuries, the G10 brings modern materials and engineering to the table. Made from high-strength G10 material – a glass-cloth laminate traditionally used in knife handles and tactical gear – these pencils have gained significant traction in professional carpentry circles. Recent surveys indicate that over 65% of master carpenters in the UK have incorporated G10 pencils into their daily toolkit, citing their durability and precision as game-changing features. Virtually unbreakable construction, eliminating the need for frequent replacements Superior marking precision compared to traditional wooden pencils Extended lifespan, making them cost-effective for professional use Consistent performance in various weather conditions The Engineering Behind the G10 The G10 material itself is a composite consisting of glass fibre cloth layers impregnated with an epoxy resin binder, compressed and baked to create an incredibly tough material. This engineering marvel results in a marking tool that’s not only exceptionally durable but also resistant to temperature changes and moisture – crucial factors in British weather conditions. The material’s properties allow for a needle-sharp tip that maintains its edge far longer than traditional materials, ensuring consistent marking quality throughout extended use. Precision Marking and Layout Capabilities The true value of the G10 pencil lies in its exceptional marking capabilities. The needle-sharp tip, combined with the tool’s balanced weight distribution, enables carpenters to achieve unprecedented accuracy in their layout work. Studies show that markings made with G10 pencils maintain their visibility up to 40% longer than traditional carpenter pencils, particularly important for complex joinery projects. Capable of producing lines as fine as 0.3mm Consistent line width throughout the marking process Enhanced visibility on both light and dark wood surfaces Superior performance on rough-sawn timber Beyond Traditional Carpenter Pencils When compared to conventional marking tools, the G10 pencil stands out in several key areas. Traditional carpenter pencils, while reliable, often require frequent sharpening and can be inconsistent in their marking quality. The G10’s durability and precision make it particularly valuable for professional carpenters working on high-end projects where accuracy is paramount. Industry data suggests that carpenters using G10 pencils spend 75% less time on marking tool maintenance compared to those using traditional pencils. Practical Applications in Professional Carpentry In real-world applications, the G10 pencil excels across a broad range of carpentry tasks. From intricate joinery work to large-scale construction projects, its versatility makes it an invaluable tool. Professional carpenters particularly praise its performance in: Fine furniture making and cabinet work Detailed architectural millwork Precise stair construction layouts Complex joint marking Timber frame construction marking The Controversy and Considerations It’s important to address the dual-purpose nature of G10 pencils. While they were originally designed with tactical applications in mind, their adoption by the carpentry industry is purely based on their superior marking capabilities. Professional carpenters should focus on the tool’s legitimate workshop applications and ensure compliance with local regulations regarding their possession and use. Recent industry guidelines recommend using G10 pencils exclusively within workshop environments, where their precision marking capabilities can be properly utilised. Making the Right Choice for Your Carpentry Toolkit When selecting a G10 pencil for professional use, several factors should be considered: Length: Optimal length is typically 4-6 inches for maximum control Grip texture: Choose models with enhanced grip patterns for better control Tip design: Look for replaceable or resharpenable tips for extended use Storage: Consider models with integrated carrying clips or protective cases For those with larger hands, some manufacturers now offer extended-length versions, providing better control during detailed work. Professional carpenters report that the initial investment in a quality G10 pencil is typically recovered within 2-3 months through reduced replacement costs and improved work efficiency. Conclusion: The Future of Precision Marking in Carpentry The G10 pencil has earned its place as a valuable tool in professional carpentry. While it may not completely replace traditional marking implements, its unique combination of durability, precision, and reliability makes it an essential addition to any serious carpenter’s toolkit. As the industry continues to evolve, tools like the G10 pencil demonstrate how modern materials and engineering can enhance even the most fundamental aspects of carpentry work. For professionals committed to delivering the highest quality craftsmanship, the G10 pencil represents not just a tool, but an investment in precision and efficiency. FAQ Is G10 slippery when wet? While G10 offers many benefits, it does have some drawbacks. One disadvantage is that it can be slippery when wet, making it difficult to grip. Is G10 hazardous? Likely to be a skin and eye irritant. Inhalation of dust may cause lung effects. Chronic/Other – Inhalation may cause lung effects. Is G-10 scratch resistant? One of them is its durability. According to Rockwell Hardness, a scale based on indentation, G10 ranks at 110, higher than other handle materials. This means that the handle is extremely hard to break, slip and incur dents and scratches. What is the H grade pencil used for? The higher numbered H pencils (9H-5H) are very light, and an excellent choice for making sketches when painting with watercolours or lettering. This is because they leave lighter marks and thus won’t show through the watercolour paints as clearly as a darker lead would. Sources [1] https://sobtactical.com/products/sob-onctractor-pencil [2] https://www.osograndeknives.com/catalog/self-defense-products/no.-2-g10-tactical-pencil-non-detectable-self-defense-tool-6.0-inch-yellow-sharp-rigid-solid-g-10-spike-handmade-in-usa-vzpeny-31313.html [3] https://www.etsy.com/market/g10_pencil