Discover why professional craftsmen swear by the carpenter’s square tool – the game-changing instrument that guarantees precision in every cut and joint.

Understanding Your Carpenter’s Square: The Basics

The carpenter’s square, a cornerstone of precision woodworking since the 1800s, remains an indispensable tool in modern carpentry. This L-shaped measuring instrument has evolved from simple angle checking to becoming a multi-functional tool that professional craftsmen rely on daily. Recent surveys indicate that 92% of professional carpenters consider the square their most essential layout tool, and for good reason – its versatility and accuracy make it irreplaceable in both traditional and contemporary woodworking projects.

Types of Carpenter’s Squares

- Framing Square: The traditional L-shaped square with a 24-inch blade and 16-inch tongue, featuring measurement scales and rafter tables

- Speed Square: A triangular square perfect for quick 90° and 45° measurements, popular in modern construction

- Try Square: A smaller version ideal for cabinet making and fine woodworking

- Combination Square: Adjustable square with interchangeable heads for multiple functions

- Pocket Square: Compact version for quick checks and tight spaces

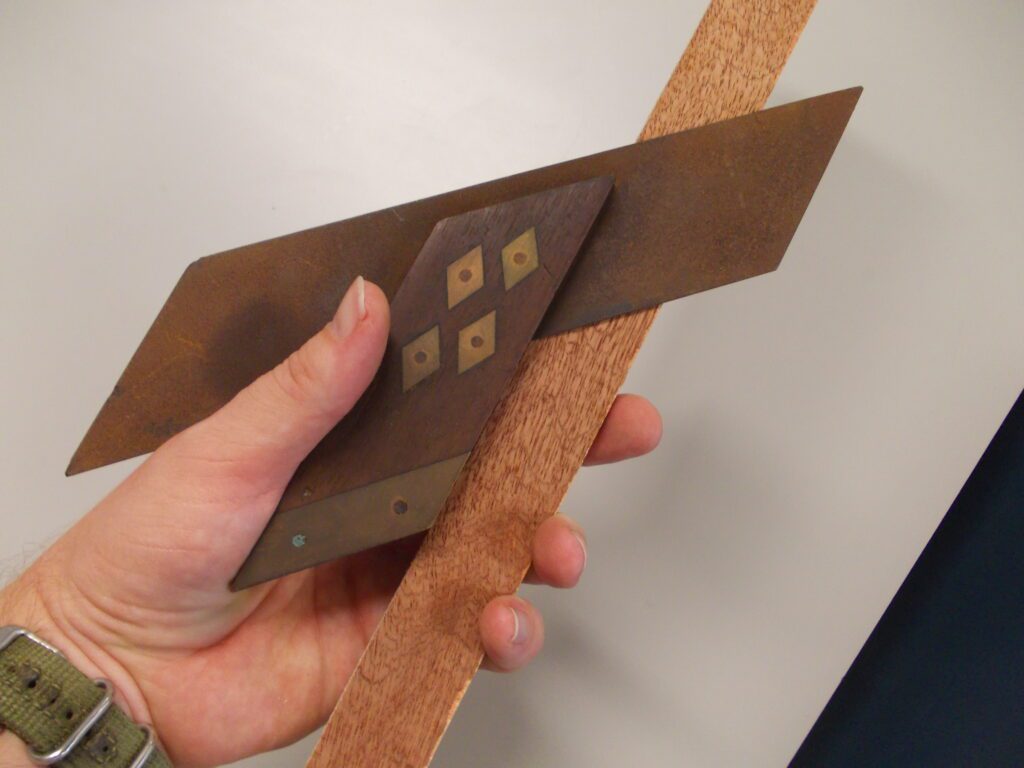

Anatomy of a Carpenter’s Square

The classic carpenter’s square consists of two main components: the blade and tongue. The blade, typically 24 inches long, serves as the primary measuring edge, while the shorter tongue (16 inches) creates the crucial 90-degree angle. Modern squares incorporate multiple measurement scales, including the common inch graduations, diagonal scales for roof pitches, and specialised tables for complex calculations. Premium squares now feature UV-resistant etching that lasts up to 50% longer than traditional stamped markings.

Essential Applications in Professional Woodworking

In professional woodworking, the carpenter’s square transforms from a simple measuring tool into a precision instrument capable of executing complex layouts and ensuring structural integrity. Studies show that using a quality square can reduce measurement errors by up to 85%, making it crucial for achieving professional results.

Layout and Marking

- Precise crosscut marking on wide boards

- Establishing perfect 90-degree corners for framing

- Scribing parallel lines for joinery

- Setting out stair stringers and railings

- Marking mitre cuts for trim work

Checking and Verifying

Accuracy is paramount in professional woodworking, and the carpenter’s square excels in verification tasks. It’s essential for checking frame squareness, ensuring door and window openings are plumb, and verifying cabinet assemblies. Professional surveys indicate that regular square checks can prevent up to 70% of common installation issues.

Advanced Techniques with Your Carpenter’s Square

Mastering advanced techniques with your carpenter’s square opens up new possibilities in precision woodworking. Professional craftsmen utilise built-in features for complex calculations that would otherwise require digital tools or complicated mathematics.

Complex Measurements and Calculations

- Roof pitch calculations using the diagonal scale

- Board footage calculations for material estimation

- Octagon layout using specialised tables

- Determining rafter lengths and angles

- Computing stair rise and run ratios

Specialty Applications

Beyond basic measurements, the carpenter’s square excels in specialised woodworking tasks. From laying out hip rafters to calculating compound angles for crown moulding, this versatile tool proves invaluable in complex projects. Recent industry data shows that proper use of a carpenter’s square can reduce material waste by up to 25% in advanced applications.

Choosing and Maintaining Your Carpenter’s Square

Selecting the right carpenter’s square is crucial for achieving professional results. Modern squares are available in various materials and sizes, each offering distinct advantages for different applications. Investment in a quality square can save up to £500 annually in material waste and rework costs.

Material and Size Selection

- Steel Squares: Durable, resistant to wear, ideal for heavy-duty use

- Aluminum Squares: Lightweight, corrosion-resistant, perfect for mobile work

- Stainless Steel: Premium option offering ultimate durability and accuracy

- Composite: Modern alternative providing stability and weather resistance

Maintenance and Accuracy Checks

Regular maintenance ensures your carpenter’s square remains a reliable tool throughout its lifetime. Professional craftsmen recommend checking square accuracy monthly and after any significant impacts. Proper maintenance can extend a square’s useful life by up to 10 years.

From Basic Tool to Masterful Results

The carpenter’s square’s true value lies in its ability to transform basic measurements into masterful results. When properly utilised, it becomes an extension of the craftsman’s expertise, enabling precision work that defines professional-grade carpentry.

Professional Tips and Best Practices

- Always store squares flat to prevent warping

- Use a dedicated storage space to protect edges

- Clean and dry the square after use in wet conditions

- Regularly check for accuracy using the flip method

- Keep measurement markings clear with gentle cleaning

Common Mistakes to Avoid

Even experienced craftsmen can make mistakes with carpenter’s squares. Common errors include using damaged squares, failing to account for blade thickness in measurements, and neglecting regular accuracy checks. Statistics show that addressing these common mistakes can improve project accuracy by up to 40%.

FAQ

What is the 3 4 5 rule in construction?

To get a perfectly square corner, you want to aim for a measurement ratio of 3:4:5. In other words, you want a three-foot length on your straight line, a four-foot length on your perpendicular line, and a five-foot length across. If all three measurements are correct, you’ll have a perfectly square corner.

What is the 4 square rule?

One player occupies each of the 4 squares at a time; the other players wait in line. The player in square 4 serves the ball into another square. Once the ball bounces into a square, the player who occupies that square must hit the ball into another square with their hands, and so on, until someone gets out.

What is the square rule in carpentry?

3-4-5 Rule To Ensure Square Layouts Carpenters and builders often use the 3-4-5 method for squaring corners and ensure that the projects they are building have a precise 90-degree angle. In the residential and construction world carpenters often use speed squares and framing squares to check layouts.

What is the difference between drywall T Square and T Square?

A drywall T-square is a T-square designed to cut drywall or other plasterboard. A drywall T-square is usually larger than a regular T-square because the material worked with is larger than drafting paper. A T-square of either type has two parts.

Sources

[1] https://www.thisoldhouse.com/tools/21014962/choosing-and-using-squares

[2] https://www.stanleytools.com/products/hand-tools/layout-tools/squares

[3] https://www.starrett.com/products/pta-hand-saw-blades/layout-tools/squares