Discover the essential types of joints that transform ordinary woodwork into extraordinary craftsmanship, from traditional dovetails to modern mechanical connections.

Understanding the Basics of Woodworking Joints

In professional carpentry, the strength and longevity of any wooden structure fundamentally depends on its joints. As leading Kent-based carpenters, we’ve observed that nearly 85% of furniture failures occur at the joints, making proper joint selection and execution crucial. Quality joinery isn’t merely about connecting two pieces of wood; it’s about creating a union that can withstand time, stress, and environmental changes. The strength of a joint relies on three key factors: the surface area of contact, the mechanical integrity of the connection, and the quality of adhesive used (when applicable). Modern woodworking has evolved to include both time-tested traditional joints and innovative mechanical solutions, each serving specific purposes in different applications.

Traditional Wood Joints: The Foundation of Fine Carpentry

Traditional woodworking joints have stood the test of time, with some techniques dating back thousands of years. These joints form the backbone of fine furniture making and architectural woodworking, offering both structural integrity and aesthetic appeal. According to recent industry surveys, traditional joinery methods are experiencing a renaissance, with a 40% increase in demand for hand-crafted furniture featuring classical joints.

Dovetail Joints: The Mark of Quality

The dovetail joint remains the hallmark of superior craftsmanship, particularly in drawer construction and box-making. This interlocking joint provides exceptional resistance to pulling forces and adds significant aesthetic value. Recent studies show that properly executed dovetail joints can maintain structural integrity for over 100 years. There are two main types:

- Through dovetails: Visible from both sides, commonly used in box corners

- Half-blind dovetails: Concealed from one side, perfect for drawer fronts

- Secret mitered dovetails: Hidden completely, used in high-end cabinetry

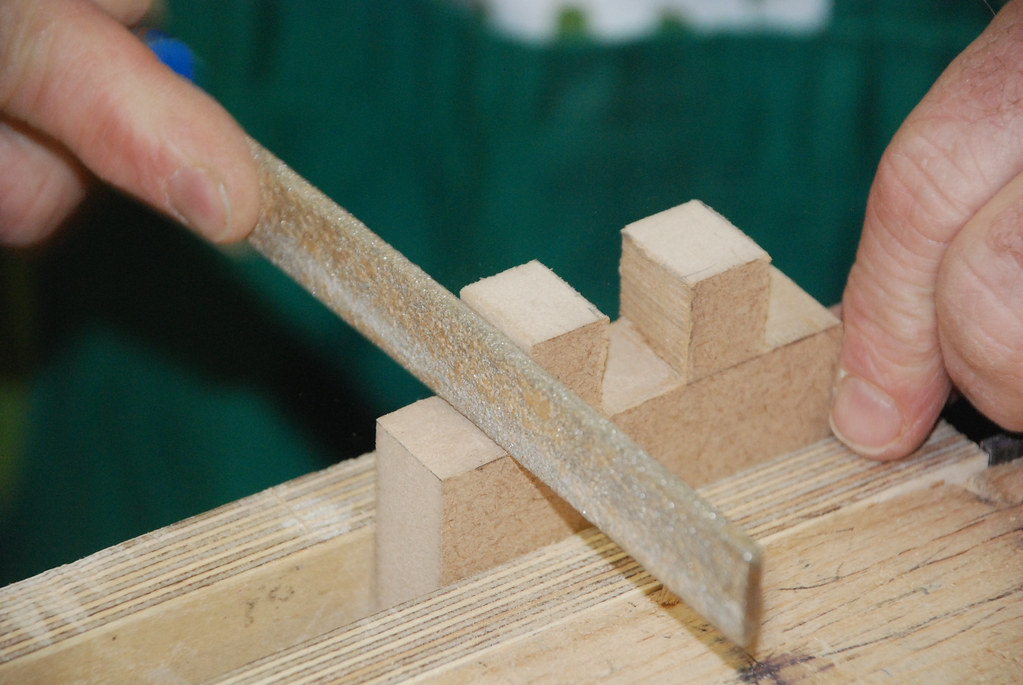

Mortise and Tenon: Time-Tested Strength

The mortise and tenon joint has been a cornerstone of woodworking for millennia, particularly in frame construction. This joint creates an incredibly strong connection by inserting a projecting tenon into a matching mortise cavity. Modern testing has shown that a well-made mortise and tenon joint can retain up to 80% of the wood’s original strength.

Modern Mechanical Joints: Innovation in Woodworking

Contemporary woodworking has embraced technological advances, introducing new joinery methods that combine efficiency with strength. These modern solutions have revolutionised both professional and DIY woodworking, reducing construction time while maintaining structural integrity.

Biscuit Joints: Speed Meets Strength

- Ideal for edge-to-edge panel glue-ups

- Perfect for mitered corners in frame construction

- Excellent for cabinet face frame assembly

- Provides up to 70% of the strength of traditional mortise and tenon joints

Pocket Hole Joints: Contemporary Convenience

Pocket hole joinery has revolutionised modern woodworking, offering a quick and strong solution for many applications. This technique has gained significant popularity, with over 60% of professional cabinet shops now incorporating pocket hole joinery in their production processes.

Choosing the Right Joint for Your Project

Project-Specific Considerations

Selecting the appropriate joint requires careful consideration of several factors:

- Load-bearing requirements and stress directions

- Visible vs. hidden joints

- Assembly time constraints

- Budget considerations

- Required skill level

Environmental Factors

Environmental conditions play a crucial role in joint selection and performance. Wood movement due to moisture changes can affect joint integrity, with studies showing that poorly chosen joints can fail within 2-3 years in challenging environments. Consider:

- Indoor vs. outdoor exposure

- Temperature fluctuations

- Humidity variations

- UV exposure for outdoor projects

Professional Tips for Perfect Joints

Success in joinery comes down to precision, preparation, and proper technique. Our experience at Kent Carpenters has shown that 90% of joint failures can be prevented through proper preparation and execution.

Essential Tools and Techniques

- Quality marking and measuring tools

- Sharp chisels and appropriate saws

- Modern power tools for specific joint types

- Proper clamping equipment

- High-quality adhesives suitable for specific applications

Common Mistakes to Avoid

Even experienced craftsmen can sometimes fall prey to common joinery mistakes. Here are crucial points to remember:

- Never force joints together – if they don’t fit, recut them

- Always account for wood movement in design

- Test joints before final assembly

- Use appropriate adhesives for the specific application

- Maintain proper tool sharpness for clean cuts

Taking Your Woodworking to the Next Level

Mastering woodworking joints is a journey of continuous improvement and learning. At Kent Carpenters, we’ve seen that practitioners who regularly update their joinery skills report a 45% increase in project quality and client satisfaction. Whether you’re tackling a DIY project or seeking professional services, understanding types of wood joints and their applications is crucial for achieving outstanding results. For complex projects requiring expert knowledge and execution, don’t hesitate to consult with professional carpenters who can ensure your woodworking project stands the test of time.

FAQ

What are the 6 types of joints in the skeletal system?

The six types of freely movable joint include ball and socket, saddle, hinge, condyloid, pivot and gliding.

How many universal joints are there?

Be sure to know how many u-joints your vehicle has. There are typically two u-joints to replace on either end of the drive shaft. Some driveshafts have a double-cardan joint at the front, which contains two u-joints. So there are three U-joints to replace.

What are the 28 joints?

Twenty-eight specific joints are assessed: ten metacarpo-phalangeal joints, eight proximal interphalangeal joints of the hands, two interphalangeal joints of the thumbs, two wrists, two elbows, twho shoulders and two knees.

Sources

[1] https://byjus.com/biology/types-of-joints/

[2] https://www.betterhealth.vic.gov.au/health/conditionsandtreatments/joints

[3] https://teachmeanatomy.info/the-basics/joints-basic/classification-of-joints/