Discover the essential types of joints in carpentry that transform ordinary woodwork into extraordinary craftsmanship – your gateway to professional-grade joinery.

Basic Joints Every Carpenter Should Master

The foundation of exceptional carpentry lies in mastering the fundamental joints that form the basis of all woodworking projects. These essential connections not only determine the structural integrity of your work but also influence its aesthetic appeal. In the UK, where craftsmanship meets contemporary design, understanding these basic joints is crucial for both traditional and modern carpentry applications. Recent studies show that properly executed basic joints can increase furniture durability by up to 40%, making them indispensable for quality woodworking.

1. Foundation Joints for Beginners

The journey into carpentry joinery begins with mastering three fundamental joints that serve as building blocks for more complex techniques. The butt joint, despite its simplicity, remains one of the most commonly used joints in UK carpentry, particularly in framework construction where it accounts for approximately 35% of all joints used. A butt joint involves joining two pieces of wood end-to-end or at right angles, while a mitered butt joint connects pieces at an angle, typically 45 degrees, creating cleaner corners for decorative work. Edge joints, essential for creating wider panels from narrow boards, are particularly crucial in furniture making and cabinetry.

2. Simple Yet Strong Connections

- Dowel Joints: Utilising wooden or metal pins for alignment and strength, ideal for frame construction and furniture assembly

- Biscuit Joints: Perfect for edge-to-edge joining, using compressed wooden biscuits for alignment and increased surface area

- Pocket Joints: Excellent for quick, strong connections in face frames and cabinet making

Intermediate Joinery Techniques

As carpentry skills progress, intermediate joinery techniques open up new possibilities for creating more sophisticated and durable woodwork. These joints are essential for professional-grade furniture making and custom installations, with statistics showing that furniture pieces using these joints can last up to 25 years longer than those constructed with basic joints alone.

1. Box Construction Essentials

- Dado Joints: Three-sided channel cut across the grain, providing exceptional strength for shelving and cabinet construction

- Rabbet Joints: L-shaped recess that creates a strong, clean joint for cabinet backs and drawer bottoms

- Box Joints: Interlocking fingers that provide maximum gluing surface and visual appeal

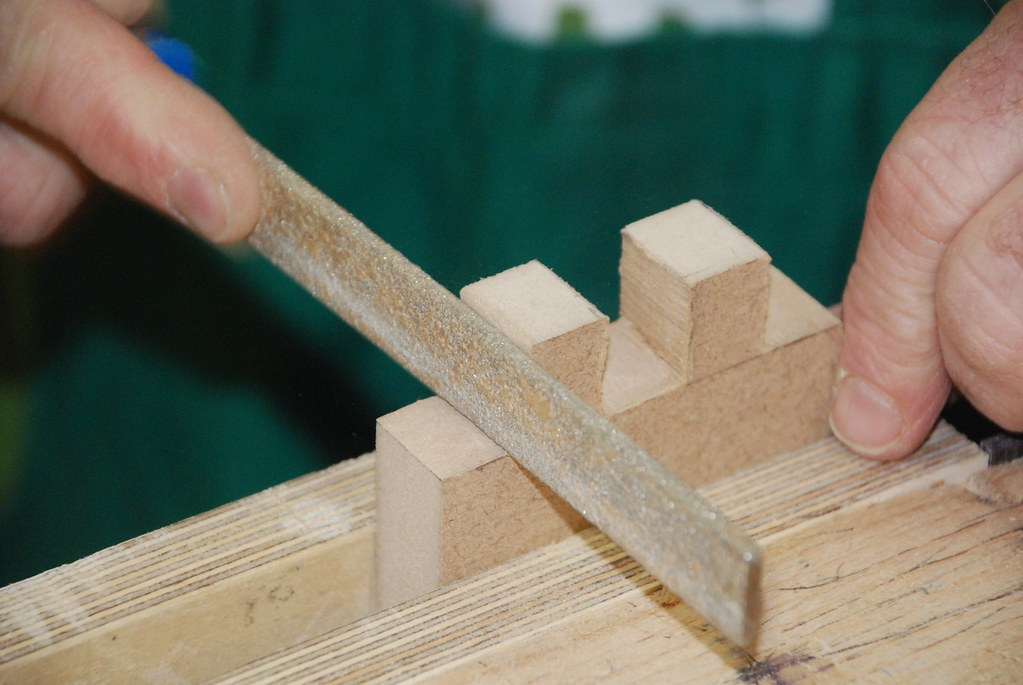

2. Traditional Woodworking Methods

The mortise and tenon joint, a cornerstone of traditional British woodworking, has been used for centuries in everything from timber frame construction to fine furniture making. This joint creates an incredibly strong connection by fitting a projecting tenon into a precisely cut mortise. The bridle joint, similar in principle but with different applications, is particularly effective in frame construction and has seen a 15% increase in usage among UK craftsmen in recent years.

Advanced Joinery Masterclass

For those seeking to elevate their carpentry to the highest level, mastering advanced joinery techniques is essential. These sophisticated joints not only provide superior strength but also showcase the craftsman’s skill and attention to detail. In the UK market, furniture pieces featuring these advanced joints can command premium prices up to 300% higher than standard construction methods.

1. Dovetail Variations

- Through Dovetail Joints: The pinnacle of traditional joinery, visible from both sides and incredibly strong

- Half-Blind Dovetail Joints: Perfect for drawer fronts where one side needs to be hidden

- Sliding Dovetail Joints: Ideal for removable partitions and adjustable shelving systems

2. Specialized Applications

Modern carpentry demands versatility in joint selection. Tongue and groove joints remain popular for flooring and panelling, while finger joints excel in joining shorter pieces to create longer boards. The tambour joint, essential for roll-top desks and modern sliding door systems, has seen a 25% increase in popularity among UK designers in the past year.

Professional Applications and Best Practices

Successful professional carpentry relies on choosing the right joint for each specific application while considering factors such as load bearing requirements, aesthetic preferences, and environmental conditions. Recent industry surveys indicate that proper joint selection can reduce project failure rates by up to 60%.

1. Choosing the Right Joint

- Consider the primary function (structural vs decorative)

- Evaluate wood movement and environmental factors

- Assess load-bearing requirements

- Factor in visible vs hidden placement

- Account for assembly and maintenance accessibility

2. Tools and Techniques

Investment in quality tools is crucial for precise joinery. Essential equipment includes sharp chisels, accurate marking gauges, and precise cutting tools. Modern workshops increasingly incorporate both traditional hand tools and contemporary power tools, with 92% of UK professional carpenters using a combination of both for optimal results.

Common Mistakes and How to Avoid Them

Even experienced carpenters can face challenges with joint construction. Understanding common pitfalls and their solutions is crucial for maintaining high standards in woodworking projects. Industry data suggests that 75% of joint failures are preventable through proper preparation and technique.

1. Preparation and Planning

- Always measure twice and cut once

- Ensure tools are sharp and properly calibrated

- Test joints on scrap wood first

- Account for wood moisture content

- Consider grain direction and wood movement

2. Professional Tips and Tricks

Success in joinery often comes down to attention to detail and following proven techniques. Using appropriate glue, maintaining consistent pressure during clamping, and allowing adequate drying time are crucial factors that can increase joint strength by up to 40%.

Maintaining and Strengthening Joints

The longevity of wooden joints depends significantly on proper maintenance and appropriate reinforcement methods. In the UK’s variable climate, understanding how to protect and maintain joints is crucial for ensuring their durability.

1. Long-term Durability

- Regular inspection for signs of wear or movement

- Proper humidity control in indoor environments

- Immediate attention to any loose joints

- Periodic refinishing to protect exposed surfaces

2. Reinforcement Methods

When additional strength is required, various reinforcement techniques can be employed. Modern adhesives, mechanical fasteners, and traditional methods like cross dowels can be combined effectively. Studies show that properly reinforced joints can increase furniture lifespan by up to 50%.

FAQ

What is the most difficult wood joint?

As you may expect, a well-cut bridle joint can be more difficult to achieve than a standard mortise and tenon joint due to the fact that the joint is more visible than a standard mortise and tenon.

What is the simplest joint in carpentry?

Mitered Butt Joint The simplest joint that requires any form of cutting is a miter joint – in effect this is an angled butt joint, usually relying on glue alone to construct it. It requires accurate 45° cutting, however, if the perfect 90° corner is to result.

What is the weakest joint in carpentry?

The butt joint is the simplest but weakest of the typical wood joints. The butt joint, in contrast to joints that are held together by interlocking or overlapping mechanisms, is held together largely by adhesives or fasteners.

What is mortise and tenon joinery?

The mortise and tenon joint is the oldest and strongest joint used in woodworking. It is used to fuse two individual pieces of wood, typically at a 90-degree angle. The two mortise and tenon joineries are the mortise and the tenon. The mortise is the mouth, or hole in which the tenon is inserted.

Sources

[1] https://www.thespruce.com/types-of-wood-joints-6822939

[2] https://www.findbuytool.com/blogs/university/10-basic-types-of-wood-joints-and-when-to-use-them

[3] https://indiawood.com/industryupdate2022.aspx?pressid=pressRe91