Discover how Hansen’s disease impacts wood preservation and learn the critical safety measures every carpenter needs to know.

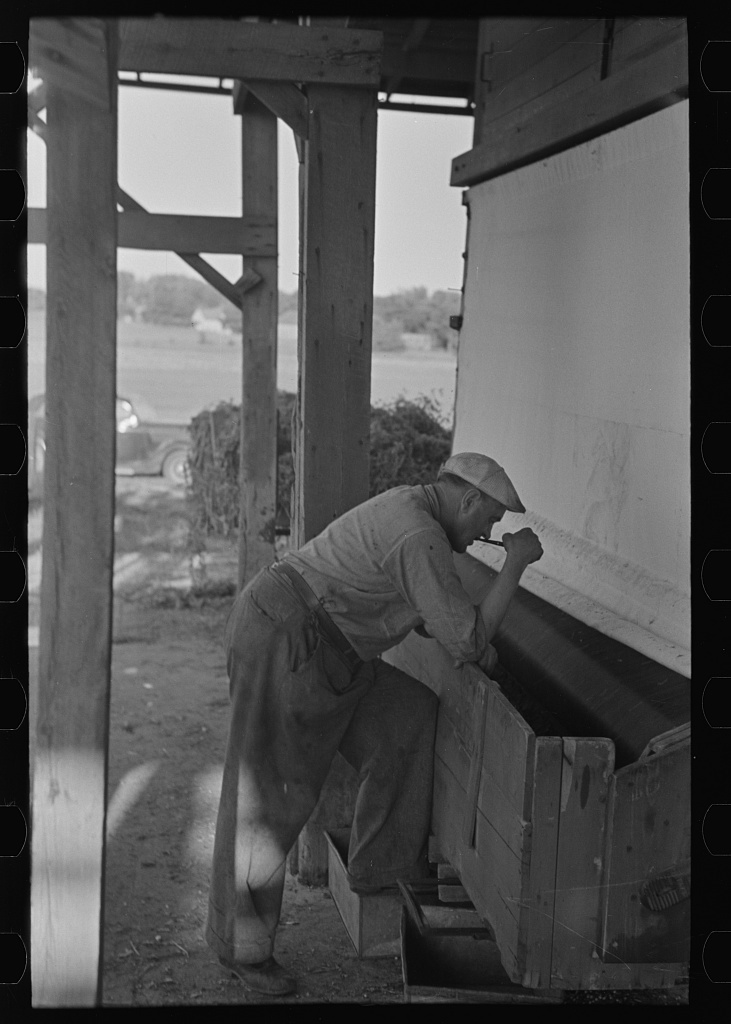

Understanding Hansen’s Disease in the Carpentry Context

Hansen’s disease, historically known as leprosy, remains a concern in the woodworking industry, particularly when dealing with imported timber and restoration projects. While the condition is rare in the UK, with fewer than 10 new cases reported annually, woodworking professionals must understand its relevance to their trade. The bacterial infection, caused by Mycobacterium leprae, can survive in certain wood environments, making it crucial for carpenters to be aware of potential risks. Contrary to common misconceptions, Hansen’s disease is not highly contagious and is completely curable with modern treatment. However, the unique interaction between the bacteria and wood materials necessitates specific safety protocols in carpentry workshops.

The Science Behind Hansen’s Disease and Wood

Research has shown that Mycobacterium leprae can survive in specific wood conditions for extended periods. The bacteria thrive in environments with high moisture content and temperatures between 27-30°C – conditions often present in timber storage facilities. Studies indicate that certain hardwoods can harbour the bacteria for up to 46 days under optimal conditions. This persistence is particularly relevant when working with imported timber from regions where Hansen’s disease is more prevalent. The bacteria’s ability to survive in wood fibres means that carpenters must be vigilant, especially when handling untreated timber or working on restoration projects involving old wood materials.

Identifying Risk Factors in Woodworking

- Working with untreated imported timber, especially from endemic regions

- Handling aged wood in restoration projects

- Processing wood in high-humidity environments

- Extended exposure to wood dust without proper protection

- Working with reclaimed timber without proper documentation

- Inadequate ventilation in enclosed workshop spaces

Essential Safety Protocols for Carpenters

Implementing robust safety measures is crucial for protecting against potential exposure to Hansen’s disease bacteria. The Health and Safety Executive (HSE) recommends a comprehensive approach to personal protective equipment (PPE) and handling procedures. Essential safety protocols include wearing FFP3-rated dust masks, maintaining proper ventilation systems, and following strict hygiene practices. Regular health screenings and risk assessments should be conducted, particularly for workers handling high-risk materials. Documentation of all timber sources and treatment procedures is essential for maintaining safety standards.

Prevention Strategies in the Workshop

- Install and maintain industrial-grade ventilation systems

- Implement regular cleaning schedules for all equipment and surfaces

- Store timber in controlled environments with appropriate humidity levels

- Use automated dust extraction systems during cutting and sanding

- Maintain detailed records of timber sources and treatment history

- Conduct regular workshop safety audits

Early Detection and Response

Recognising potential symptoms of Hansen’s disease is crucial for early intervention. Workers should be trained to identify signs such as discoloured skin patches, numbness, and muscle weakness. If exposure is suspected, immediate medical attention should be sought. Workshop managers should establish clear reporting procedures and maintain relationships with occupational health services. Early detection significantly improves treatment outcomes, with 95% of cases being fully curable when identified promptly.

Modern Treatment Methods and Support

Current medical approaches to Hansen’s disease involve multi-drug therapy (MDT), which has proven highly effective. The treatment typically spans 6-12 months, depending on the type and severity of infection. The NHS provides comprehensive support for affected individuals, including specialised treatment centres and rehabilitation services. Employers should be prepared to provide necessary workplace accommodations and support during treatment periods. Insurance coverage and occupational health services should be reviewed to ensure adequate protection for workers.

Legal and Insurance Considerations

- Compliance with Control of Substances Hazardous to Health (COSHH) Regulations

- Regular review and update of workplace risk assessments

- Adequate employer’s liability insurance coverage

- Documentation of safety training and procedures

- Implementation of accident reporting protocols

- Regular consultation with health and safety representatives

Professional Development and Training

Ongoing education about biological hazards in woodworking is essential for maintaining a safe working environment. Professional certification programmes, such as the City & Guilds Level 3 in Wood Occupations, now include modules on biological safety. Workshop managers should ensure all staff receive regular updates on safety protocols and new research findings. Training should cover proper use of PPE, emergency procedures, and risk assessment techniques.

Future-Proofing Your Workshop

Adapting to evolving safety standards requires a forward-thinking approach. Investment in modern equipment, including automated handling systems and advanced ventilation technology, can significantly reduce exposure risks. Regular updates to safety protocols based on new research and guidelines ensure continued protection. Implementing digital tracking systems for timber sources and treatment records helps maintain comprehensive safety documentation.

Expert Recommendations and Best Practices

- Conduct annual review of safety procedures and update as needed

- Invest in advanced dust extraction and ventilation systems

- Provide regular health screenings for all workshop personnel

- Maintain detailed records of timber sources and treatments

- Establish partnerships with occupational health services

- Regular consultation with industry safety experts

Conclusion: Maintaining Safety Without Compromise

While Hansen’s disease presents a minimal risk in modern woodworking, maintaining robust safety protocols is essential for protecting workers and ensuring regulatory compliance. By implementing comprehensive safety measures, providing proper training, and staying informed about current research, workshops can effectively manage potential risks while maintaining productivity. Regular review and updates of safety procedures, combined with proper documentation and support systems, create a secure working environment that protects both workers and business interests.

FAQ

Can leprosy be cured completely?

Leprosy is curable. Healthcare providers use a combination of three antibiotics, known as multidrug therapy (MDT), to kill the bacteria.

Why are 95 people immune to leprosy?

Around 95 percent of people cannot be infected because their immune system can fight off the bacteria that causes Hansen’s disease. In addition, you must have prolonged, close contact with someone with untreated Hansen’s disease over many months to catch the disease.

What does a person look like with leprosy?

Symptoms don’t appear for at least a year following infection, and most people don’t see the signs until five to seven years have passed. The most common early leprosy symptoms are patches of skin that are either lighter than the surrounding skin or reddish. They may be numb.

Sources

[1] https://www.cdc.gov/leprosy/about/index.html

[2] https://en.wikipedia.org/wiki/Leprosy

[3] https://my.clevelandclinic.org/health/diseases/23043-leprosy-hansens-disease